Sustainable manufacturing increasingly relies on innovative materials that reduce environmental impact while maintaining high-quality standards. Among these solutions, recycled glass enables manufacturers to conserve energy, lower emissions, and optimize resource use. Its integration not only supports eco-conscious production but also enhances efficiency and long-term material performance.

By adopting circular practices, manufacturers can minimize waste streams and create value for both businesses and consumers. Properly processed recycled glass ensures measurable energy and resource savings across production cycles. Forward-thinking companies leverage these practices to strengthen sustainability initiatives and meet evolving regulatory and market demands.

Environmental Benefits of Using Recycled Glass

Recycled glass reduces the need for raw materials, preserving valuable natural resources such as sand, soda ash, and limestone. Using post-consumer glass significantly lowers energy consumption during manufacturing compared to traditional methods. Manufacturers can decrease greenhouse gas emissions while actively supporting broader sustainability initiatives and corporate responsibility goals.

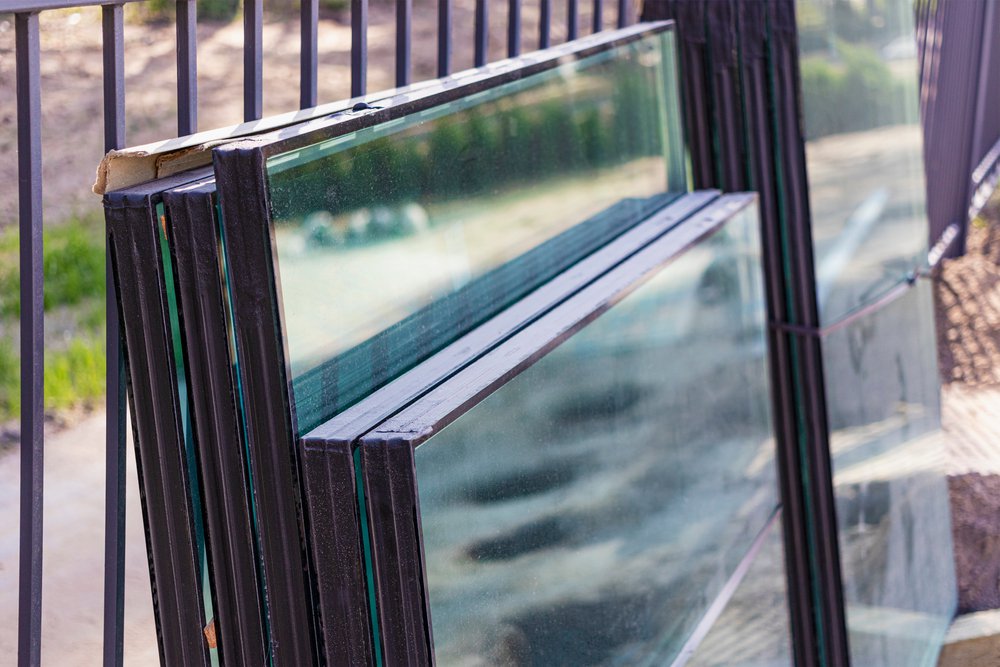

Processing recycled glass requires thorough sorting and removal of contaminants to maintain consistent quality and structural performance. Impurities can weaken glass strength, reduce transparency, and compromise insulation properties in high-performance applications. Efficient recycling practices, including recycling old glass units, ensure materials remain usable while maintaining functionality and durability.

Circular manufacturing strategies incorporating recycled glass help minimize landfill waste while promoting long-term ecological sustainability. Glass can be reused multiple times without notable loss in quality, performance, or aesthetic appeal. Companies benefit economically from reduced raw material and energy costs while demonstrating environmental stewardship.

Contribution to a Circular Economy

Using recycled glass is integral to a closed-loop system that minimizes waste while optimizing resource efficiency. Incorporating this material allows manufacturers to maintain high product standards without increasing environmental impact. Closed-loop practices also strengthen supply chain sustainability by keeping materials continuously in use.

Cleanly processed recycled glass can replace a substantial portion of virgin materials in new production processes. Its use supports LEED certification and other green building standards, providing measurable sustainability benefits. Thoughtful integration encourages manufacturers to innovate while reducing operational carbon footprints over time.

Implementing circular strategies with recycled glass enhances corporate environmental responsibility and improves stakeholder perception significantly. Companies prioritizing recycled content demonstrate quantifiable reductions in greenhouse gas emissions annually. Long-term adoption fosters investment in recycling infrastructure and promotes more sustainable manufacturing practices overall.

Reducing Carbon Emissions Through Sustainable Manufacturing

Incorporating recycled glass into production delivers measurable environmental benefits while improving operational efficiency. Lower energy requirements reduce greenhouse gas emissions and support sustainability objectives. Manufacturers can implement practical strategies to minimize carbon output while maintaining product quality.

Key Ways to Reduce Carbon Emissions:

- Optimize Furnace Operations: Adjust temperature settings and furnace cycles to maximize energy efficiency during glass melting.

- Increase Recycled Content: Replace a portion of virgin raw materials with clean, processed recycled glass to lower energy use.

- Implement Waste Heat Recovery: Capture and reuse excess heat from furnaces to reduce fuel consumption and emissions.

- Use Energy-Efficient Equipment: Upgrade to modern, insulated furnaces and auxiliary systems that consume less energy.

- Monitor and Maintain Systems: Regular inspections prevent energy losses, ensuring recycled glass melts efficiently and consistently.

Maintaining Quality Through Proper Sorting and Processing

Proper sorting and processing are essential to ensure recycled glass maintains consistent quality, safety, and performance standards. Manufacturers must carefully separate, clean, and crush materials to avoid contamination that could compromise final products. Strict adherence to processing protocols guarantees recycled glass performs comparably to virgin materials in multiple applications.

Key Steps for Maintaining Recycled Glass Quality:

- Sort glass by color, removing any non-glass contaminants to prevent defects.

- Clean thoroughly using automated systems to eliminate dust, labels, and residual materials.

- Crush and size glass to meet production specifications for insulation, laminated, or tempered applications.

- Implement optical sorting technologies to separate impurities and ensure uniformity.

- Conduct routine testing for optical clarity, thermal performance, and mechanical strength.

Future Trends in Recycled Glass Usage

Advancements in recycling technology are increasing the percentage of glass that can be reintroduced into manufacturing. Emerging techniques improve quality, color separation, and impurity removal. Industry adoption of reclaimed materials is expected to grow rapidly over the next decade.

Governments and environmental bodies incentivize the use of recycled content through tax credits and regulatory frameworks. Manufacturers that proactively integrate reclaimed glass gain competitive advantages and meet sustainability mandates. Tracking recycled content contributes to corporate reporting and green building certifications.

Consumer demand for eco-conscious products drives continued innovation in glass recycling and sustainable manufacturing practices. Architects and developers increasingly choose materials that demonstrate measurable environmental responsibility and long-term performance benefits. Recycled content supports high-performance IGUs while advancing energy efficiency and durability.

Driving Sustainability Through Recycled Glass

Using recycled materials in glass production, Insul-Lite Manufacturing™ reduces energy consumption, lowers emissions, and supports the circular economy for modern construction projects. Sustainable practices provide measurable environmental benefits while maintaining high-quality standards and building performance. Manufacturers embracing eco-conscious production demonstrate commitment to responsible practices and industry leadership.

Integrating reclaimed materials also encourages innovation, optimizes resource use, and enhances architectural flexibility. Forward-thinking approaches balance efficiency, aesthetics, and sustainability in building materials. Partnering with knowledgeable suppliers ensures long-term success while protecting both the planet and project performance. Consult with experts to integrate recycled materials into your projects.