As autumn fades and the first cold fronts sweep across North America, no one wants to discover that their insulating glass units are underperforming. Compromised window seals can quickly turn into a costly headache, letting drafts creep inside, fogging up valuable glazing, and driving up heating bills. For anyone in the business of delivering comfort, efficiency, and long-term value, preventing seal failures before the coldest months is essential.

Why Window Seals Play a Critical Role

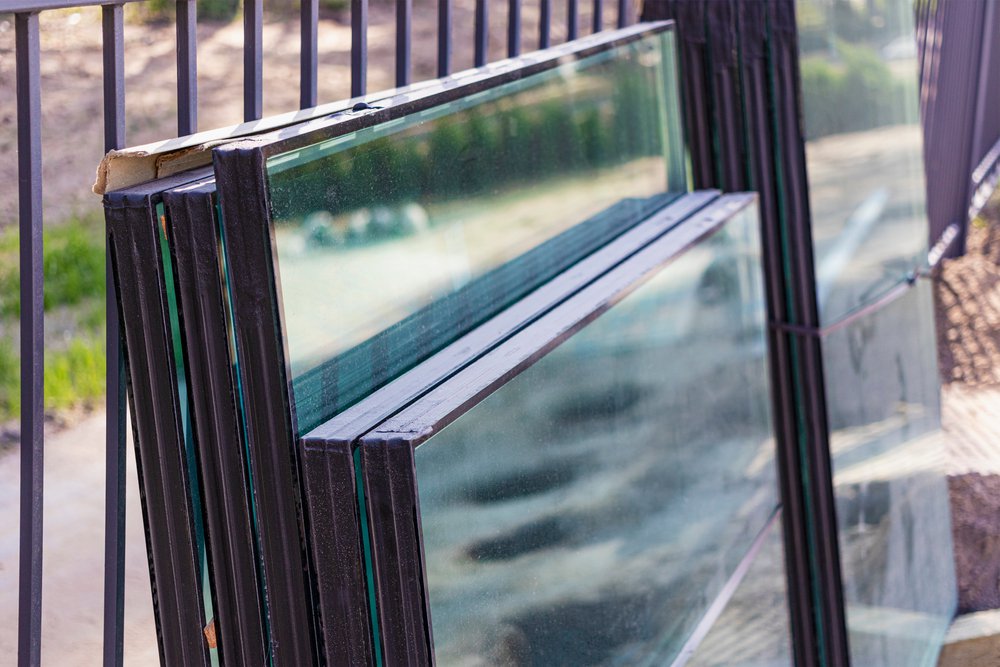

Every insulating glass unit relies on its seals to do the heavy lifting. They lock in the insulating gases that boost thermal performance and block out the moisture that leads to condensation between panes. Without durable seals, even the best glazing, coatings, and spacer systems lose their ability to perform as designed.

Window seals are more than a protective edge around glass. They are an essential part of the building envelope that maintains indoor comfort, reduces HVAC demand, and protects investments in high-performance glazing. When seals break down, the effects are felt immediately in energy efficiency, occupant comfort, and overall building durability.

Common Causes of Seal Failures

Even with quality materials, several factors can contribute to premature seal failure. These issues often begin small but can compromise entire systems over time, leading to noticeable performance loss. Recognizing common causes helps ensure the right preventive measures are put in place.

- Manufacturing flaws: Inconsistent application or substandard materials during production can create weak points.

- Installation stress: Mishandling sealed units or improper framing can compromise seals from the start.

- Environmental pressures: UV exposure, temperature swings, and humidity cycles gradually wear down sealants.

- Aging materials: Over time, even well-installed units face natural breakdown. A 20- to 30-year lifespan is common, but subpar seals can fail much earlier.

Each of these factors emphasizes why working with proven materials and reliable manufacturers is essential. When seals are designed and installed correctly, the risk of failure drops significantly, and the building envelope maintains its long-term performance.

Telltale Signs of Failing Window Seals

Catching problems early makes all the difference. Contractors and manufacturers can often identify seal failures through visible and performance-based indicators. Recognizing the warning signs allows for timely intervention before problems escalate.

- Fogging or condensation between panes: Moisture that seeps past failed seals condenses inside the unit.

- Distorted glass appearance: A hazy or dirty look that cannot be cleaned from the surface.

- Comfort issues: Cold drafts or hot spots near windows that were once efficient.

- Rising energy costs: A sudden spike in heating bills during fall and winter.

- Visible damage at the edges: Cracking, separation, or other visible issues along the spacer line.

By addressing these signs promptly, building professionals can protect the integrity of the unit and avoid costly mid-winter replacements. Early intervention ensures performance and comfort remain intact during peak heating season.

Why Winter Exposes Weakness in Window Seals

The colder months bring out the worst in failing seals. Lower outdoor temperatures create stronger pressure differences between indoor and outdoor air, which means even the smallest leaks become noticeable. Condensation and frost highlight hidden weaknesses, while heating systems work harder to maintain consistent temperatures.

A compromised building envelope in summer might be an inconvenience, but in winter it becomes a serious problem. Moisture from failed seals can freeze inside units, accelerating deterioration and leading to costly replacements. That makes late autumn the ideal time to inspect and address window seals before the real cold begins.

Preventing Seal Failures with Smarter Choices

The most effective way to avoid winter headaches is by making informed choices about materials, manufacturing partners, and installation practices. Prevention begins with understanding the steps that most effectively protect seals from stress and wear.

- High-quality IGUs: Choose sealed units with warm-edge spacers and proven dual-seal systems designed for long-term performance.

- Proper installation: Handling sealed units carefully, ensuring frame compatibility, and preventing racking stress extend seal life.

- Routine inspections: Regular maintenance schedules, especially in the fall, catch small problems before they become serious.

- Upgrading older units: Double-pane glass from decades ago rarely performs to modern standards. Replacing them with today’s triple-pane or advanced IGUs reduces the risk of failures while boosting performance.

Each of these practices strengthens the role of window seals in ensuring comfort, energy efficiency, and long-term reliability. When combined, they reduce risk while enhancing the value of every project.

Window Seals and Long-Term Building Performance

High-performing window seals do more than prevent fogging. They safeguard energy efficiency targets, extend the service life of building envelopes, and help projects meet demanding certifications such as Passive House or LEED. A failure at the seal compromises the entire system, while a durable seal ensures consistent performance across the life of the unit.

In both residential and commercial projects, window seals are a critical line of defense against energy loss and moisture intrusion. As building codes tighten and clients demand higher performance, choosing the right insulating glass and seal technologies has become a defining factor in long-term success.

Action Steps Before the Winter Season

As colder weather approaches, it is essential to act quickly and decisively. Seal failures rarely resolve on their own and often worsen with time. Taking proactive measures now ensures projects remain efficient, comfortable, and durable through the season.

- Inspect sealed units for early signs of fogging, haze, or visible edge damage.

- Evaluate building performance for unusual drafts or uneven temperatures near windows.

- Address problems proactively rather than waiting for failures to worsen under winter stress.

- Source replacements from manufacturers with proven quality control, durable seal systems, and modern spacer technologies.

Implementing these steps prevents costly mid-season disruptions. They also reinforce trust in the products and systems used, proving the long-term reliability of the building envelope. Taking action before the snow arrives means fewer emergency repairs and greater satisfaction from end users.

Avoid Winter Failures with Quality Window Seals

Seal failures may start small, but their impact grows quickly once temperatures drop. Moisture, drafts, and lost energy efficiency create avoidable challenges that weaken the performance of any building envelope. By prioritizing quality window seals, inspecting units before winter, and upgrading older glazing with modern technology, building professionals protect both occupants and long-term investments.

Insul-Lite Manufacturing™ is committed to delivering durable sealed units with advanced warm-edge spacers and reliable sealant systems. Our expertise in producing high-performance insulating glass helps contractors and manufacturers deliver the efficiency, comfort, and longevity their projects demand. Protect your projects from winter headaches with sealed units built to last. Contact us today.