Insulated glass units play a critical role in enhancing energy efficiency and occupant comfort in modern buildings. Choosing the right insulated glass units ensures that structures maintain consistent thermal performance and minimize energy loss. Improper selection or installation can quickly compromise the expected benefits of these advanced glass systems.

Architects, builders, and homeowners often underestimate the impact of seal quality and spacer choice on long-term performance. Condensation, heat transfer, and material degradation frequently result from overlooked details in IGU specification. Careful planning and adherence to best practices prevent these common failures and extend building longevity.

Thermal Performance Issues in Insulated Glass Units

Inadequate thermal performance in insulated glass often stems from incorrect gas fill or improper Low-E coatings. Heat loss through windows is a leading contributor to higher energy consumption. Choosing insulated glass that meets project specifications can significantly reduce heating and cooling costs.

Temperature fluctuations inside buildings frequently lead to discomfort for occupants. Drafts and uneven heating are typically linked to poorly performing IGUs. Implementing quality-assured units addresses both energy efficiency and interior comfort requirements effectively.

Condensation and fogging indicate underlying issues with sealing or spacer materials. These problems not only reduce transparency but may also damage window frames over time. Early identification and correction prevent more significant maintenance concerns later.

Installation and Handling Guidelines for Insulated Glass Units

Incorrect handling of insulated glass units during installation can create stress points and increase the risk of failure. Training glazing teams on proper transport, lifting, and fit techniques significantly reduces these potential issues. Careful attention during installation ensures that IGUs maintain their thermal performance and durability over time.

Proper procedures during installation are critical to achieving long-lasting IGU performance. Key steps include:

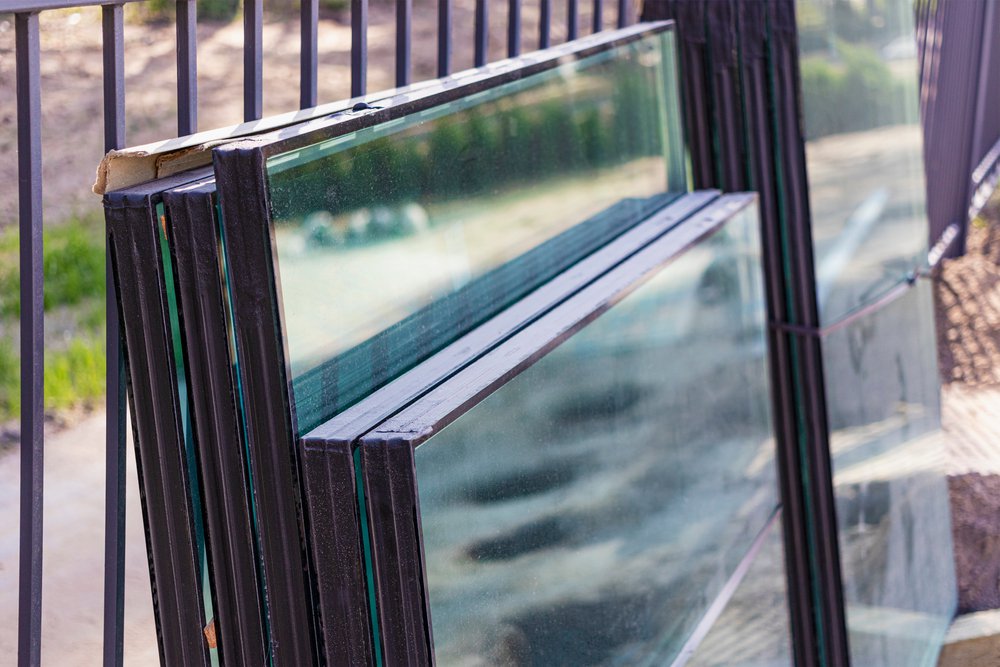

- Use appropriate transport methods: Always handle units vertically on secure racks with padding to prevent cracks or chips.

- Ensure precise alignment and support: Level and properly anchor windows to avoid stress or warping over time.

- Apply protective measures on-site: Use films and avoid direct contact with hard surfaces to maintain glass integrity.

- Coordinate with stakeholders: Confirm drawings, site conditions, and specifications before installation to prevent errors.

- Inspect and verify after installation: Check seals, spacers, and overall fit to ensure units perform as designed.

Following these best practices helps reduce condensation, air leakage, and premature IGU failure. Consistent installation allows insulated glass units to provide the expected energy efficiency and comfort in every building.

Spacer Systems and Seal Quality in Insulated Glass Units

Spacer bars separate the glass panes and keep a consistent cavity width in insulated glass units. The choice of spacer material directly influences thermal bridging, energy retention, and long-term performance. High-quality seals help keep the gas fill intact and reduce the risk of condensation or fogging inside the unit.

Attention to spacers and seals is critical for maximizing IGU longevity and performance. Key considerations include:

- Choose the right spacer type: Select between aluminum, Super Spacer, or Eneredge based on desired thermal performance.

- Maintain uniform installation: Maintain consistent spacing to avoid stress points and reduce the risk of seal failure.

- Select high-quality sealants: Use durable, UV-resistant sealants that preserve gas fill and prevent internal moisture buildup.

- Inspect regularly: Verify the integrity of spacers and seals to detect early signs of wear or failure.

- Consider thermal performance impact: Proper spacers and seals minimize heat transfer and improve overall energy efficiency.

Following these practices ensures that insulated glass units deliver consistent performance and maintain occupant comfort. Proper attention to spacers and seal quality directly impacts durability and long-term efficiency.

Low-E Coatings for Performance and Comfort

Low-emissivity coatings reduce heat transfer through insulated glass units without affecting natural light. These coatings reflect infrared energy, keeping interiors warmer in winter and cooler in summer. Projects that integrate Low-E enhanced IGUs demonstrate measurable energy savings over conventional glazing.

Placement of Low-E layers within the IGU cavity determines performance outcomes. Inner-pane coatings may optimize winter heat retention, while outer-pane coatings reduce solar gain. Understanding coating specifications is critical to achieving design intent and energy code compliance.

Low-E integration also contributes to occupant comfort and furniture preservation. Limiting UV exposure protects interiors from fading and damage. Combining coatings with proper IGU assembly maximizes long-term benefits for building occupants.

Energy Efficiency and Sustainability

High-performance insulated glass units contribute to sustainable construction practices. Reducing energy consumption lowers greenhouse gas emissions and operational costs. Selecting sustainably designed IGUs with environmentally friendly materials supports long-term building certifications.

Longer-lasting units decrease replacement frequency and minimize construction waste. Choosing durable products also reduces the environmental impact associated with frequent repairs. Lifecycle analysis of IGUs provides measurable sustainability advantages for building owners.

Thermal efficiency impacts HVAC system sizing and operational expenses. Well-insulated windows reduce equipment workload, extending lifespan and improving overall reliability. Properly specified IGUs are a fundamental component of energy-conscious design strategies.

Partnering with Specialized IGU Suppliers

Working with a dedicated supplier improves the quality, consistency, and performance of insulated glass units. Expertise in assembly, material selection, and testing allows each unit to meet exacting standards. Technical guidance from specialists helps prevent costly errors in both design and installation.

Specialized suppliers offer access to advanced Low-E coatings, warm-edge spacers, and custom configurations. These options address unique architectural requirements and evolving energy codes efficiently. Collaboration with knowledgeable manufacturers guarantees reliable performance and predictable project outcomes.

Timely delivery and responsive support are additional benefits of partnering with experienced IGU producers. Projects benefit from minimized lead times, accurate logistics, and ongoing technical assistance. Reliable sourcing enhances contractor confidence and supports superior building performance.

Ensuring Lasting Comfort and Efficiency

High-quality insulated glass units provide superior thermal insulation, noise reduction, and occupant satisfaction consistently. Reliable IGUs contribute to energy savings, reduce HVAC stress, and improve overall comfort effectively. Selecting proven products enhances durability and lowers long-term maintenance costs significantly.

Insul-Lite Manufacturing™ crafts insulated glass units designed for consistent performance and long-lasting comfort. Their precision assembly and quality checks ensure IGUs work reliably in any building. Connect with experts to prevent IGU performance issues and ensure lasting comfort and efficiency.