Windows have evolved into performance systems that influence comfort, efficiency, and aesthetics in modern architecture. Innovations like sealed glass units now define how buildings maintain insulation, reduce condensation, and ensure long-term clarity. Precision engineering and sustainable materials combine to deliver superior durability while supporting energy-efficient design goals.

Each layer within these systems contributes to consistent thermal control and structural integrity. Carefully crafted spacers, coatings, and seals prevent moisture intrusion while maintaining optical performance. Through ongoing advancements, manufacturers continue to refine glass construction methods that meet both environmental and architectural standards.

What Sealed Glass Units Are and How They Function

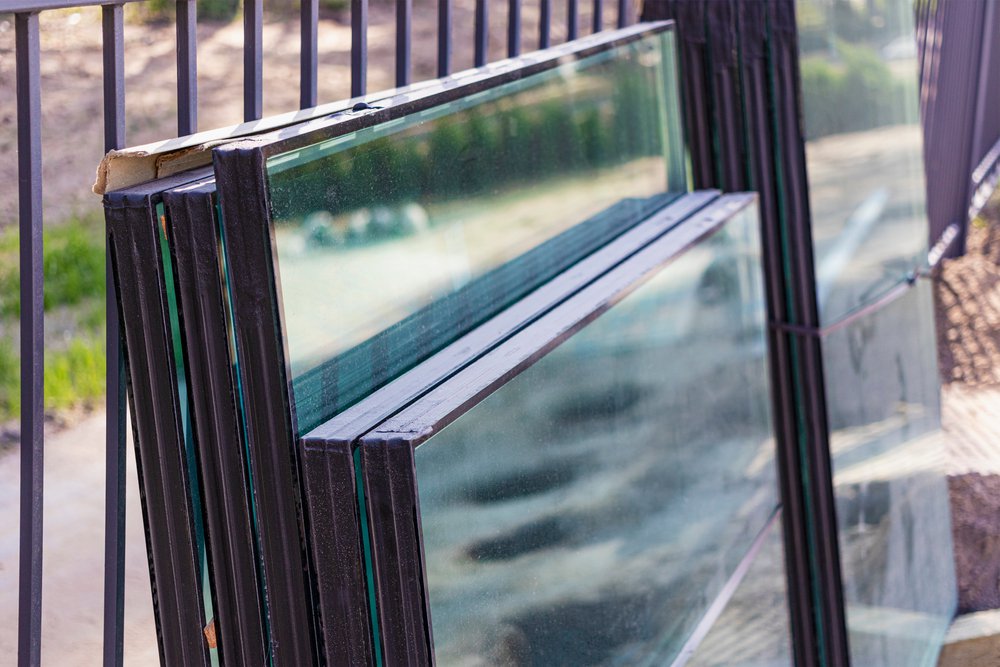

A sealed glass unit, often called an insulating glass unit (IGU), consists of two or more panes separated by a spacer. The edges are tightly sealed to create an insulating airspace that minimizes temperature transfer and condensation. This configuration forms the foundation of modern energy-efficient windows in both homes and commercial buildings.

When constructed properly, eco-friendly sealed glass units improve indoor comfort by maintaining stable interior temperatures regardless of external conditions. The air or inert gas layer between panes serves as a thermal barrier, enhancing insulation properties significantly. Innovations now focus on optimizing these gaps using sustainable materials and coatings to improve performance and reduce environmental impact.

Every detail in a sealed glass unit’s design, from glass thickness to gas fill composition, influences its effectiveness. Precision alignment of each component ensures even pressure distribution and long-term structural stability. Therefore, consistent quality during production directly determines the reliability and efficiency of finished window systems.

The Importance of Moisture Control in Sealed Glass Units and Long-Term Durability

Moisture infiltration is one of the greatest threats to sealed glass unit performance and longevity. Once moisture breaches the seal, condensation forms between panes, reducing visibility and thermal insulation. High-quality sealants and desiccants are essential in preventing vapor penetration and maintaining lasting clarity.

Durability depends on the combination of proper edge sealing and controlled environmental exposure throughout the product’s lifespan. Manufacturers employ multi-layer sealing systems designed to resist temperature fluctuations and UV degradation. Research and development in energy-efficient sealed glass units show that proper construction minimizes heat loss and protects internal materials from moisture damage.

While visible fogging may appear gradual, it often signals deeper seal deterioration that compromises the unit’s insulation value. Preventing such degradation requires selecting sealants engineered for flexibility and resistance to thermal cycling. With consistent maintenance, sealed glass units retain their functional and visual integrity for many years.

How Poor Sealing Impacts Thermal Performance and Fogging Resistance

Even minor imperfections in edge sealing can drastically reduce a window’s insulation efficiency. Air leaks or weak bond lines allow gas escape and moisture entry, undermining the intended thermal barrier. Consequently, energy consumption increases while occupants experience reduced comfort levels throughout the seasons.

Fogging inside sealed glass units indicates that internal desiccants can no longer absorb infiltrated moisture effectively. The resulting condensation obscures transparency and leads to visible stains between panes. Over time, compromised seals also promote mold formation and frame corrosion, requiring costly replacements.

High-performance sealants play a crucial role in preventing such failures through elasticity and adhesion retention under stress. Their ability to withstand extreme expansion or contraction ensures that sealed glass units remain airtight. Thus, precision application during manufacturing defines how well a window resists fogging and maintains consistent energy performance.

The Role of Spacers and Sealants in Maintaining Glass Integrity

Spacers are critical components that determine the distance between panes, ensuring structural balance and preventing glass contact. Modern options like warm-edge spacers reduce thermal bridging, enhancing the insulation capacity of sealed glass units. Selecting the right spacer material affects both energy efficiency and condensation resistance across temperature variations.

Sealants complement spacers by securing all components into a single airtight system resistant to stress and vibration. Multi-stage sealing systems combine primary and secondary materials to protect internal gases and maintain unit rigidity. Furthermore, each layer must bond effectively with glass surfaces to avoid premature delamination.

Innovations in spacer and sealant design continue to improve manufacturing consistency and sustainability outcomes. Advances in the tempering process further enhance both safety and durability in modern glass production. Together, these components safeguard structural performance while ensuring long-term visual clarity.

Precision Manufacturing: The Foundation of Reliable Performance

Manufacturing precision defines how effectively sealed glass units perform under changing environmental stresses. Every step, from glass cutting and washing to spacer alignment and seal application, requires stringent quality controls. Even microscopic debris or uneven surfaces can jeopardize adhesion and compromise thermal performance.

Advanced production environments utilize automated sealing and inspection systems to maintain uniformity and repeatability. This ensures each sealed glass unit meets rigorous standards before shipment to window fabricators or contractors. As automation improves, production errors decline, directly enhancing product reliability and customer satisfaction.

Consistency in quality also supports broader sustainability objectives by reducing waste and minimizing product failure rates. Manufacturers prioritizing precision avoid rework costs and extend material efficiency across operations. Ultimately, precision-based craftsmanship results in glass systems that remain clear, strong, and energy-efficient for decades.

Why Consistent Manufacturing Standards Ensure Consistent Results

Reliable performance in sealed glass units depends on uniform production practices that maintain quality across every batch. Consistent manufacturing minimizes variations that could affect clarity, insulation, or durability. These standards help ensure that every installation meets performance expectations under real-world conditions.

To ensure long-term performance, manufacturers rely on standardized tests such as:

- Thermal cycling tests simulating temperature extremes.

- Gas retention assessments verifying insulation performance.

- Moisture penetration evaluations confirming seal durability.

Building Confidence Through Quality Craftsmanship in Sealed Glass Units

Reliable sealed glass units represent the culmination of technical skill, material science, and manufacturing precision. Their ability to resist fogging, retain insulation, and maintain clarity depends entirely on construction excellence. Consequently, every decision in production, from glass selection to final sealing, affects overall window performance and lifespan.

Clients seeking long-lasting solutions value suppliers that uphold rigorous standards and consistent quality in every unit produced. Such commitment guarantees dependable energy performance while reducing maintenance and replacement costs over time. Furthermore, partnering with experts ensures every project receives glass built for durability and precision.

Insul-Lite Manufacturing™ crafts sealed glass units with precision to ensure clarity, insulation, and long-lasting performance. Partner with Insul-Lite for glass solutions engineered to exceed performance standards and deliver enduring value across every project.